Compressors have been a cornerstone in many industries for centuries, evolving significantly from their humble beginnings to modern-day technological marvels. Whether in manufacturing, energy production, or cooling systems, compressors play a pivotal role in ensuring efficiency and performance. In this comprehensive overview, we delve into the history, development, and types of compressors, helping you understand their critical importance and evolution over time.

The Origins of Compressors: Ancient Beginnings

The history of compressors dates back to ancient civilizations. Early versions of compressors were used to increase the temperature in furnaces for melting metals such as copper, tin, and iron. These early devices, known as “blowers,” played a crucial role in shaping modern compressor technology. The concept of compressed air began to evolve as these devices were used to direct airflow into furnaces, raising their temperatures significantly.

Ctesibius’ Water Organ: The First Practical Use of Compressed Air

One of the first known applications of compressed air can be traced to Ctesibius of Alexandria in the 3rd century BC. His invention, the water organ, utilized compressed air to produce musical sounds. This early use of compressed air marked a significant milestone in the development of air compression technology, laying the foundation for future innovations.

The Rise of Industrial Compressors: A New Era

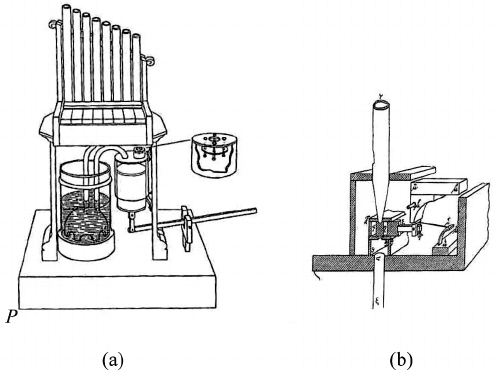

By the late 19th century, compressors became more than just basic tools and began to evolve into industrial machines. Compressor technology became integral to the advancement of manufacturing and energy sectors. In the 1850s, the invention of the Roots blower by Philander and Francis Roots marked a significant milestone in compressor development. This design, featuring figure-eight rotors that rotated in opposite directions, became a prototype for many modern compressors.

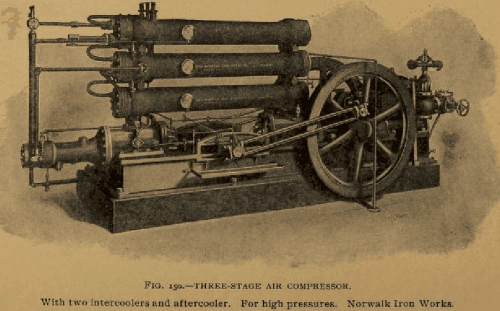

Piston and Centrifugal Compressors: The Key Advancements

The late 19th and early 20th centuries saw the development of piston and centrifugal compressors, which offered enhanced efficiency and power. These compressors were widely adopted across various industries, providing essential support for high-demand tasks such as energy production and industrial processes.

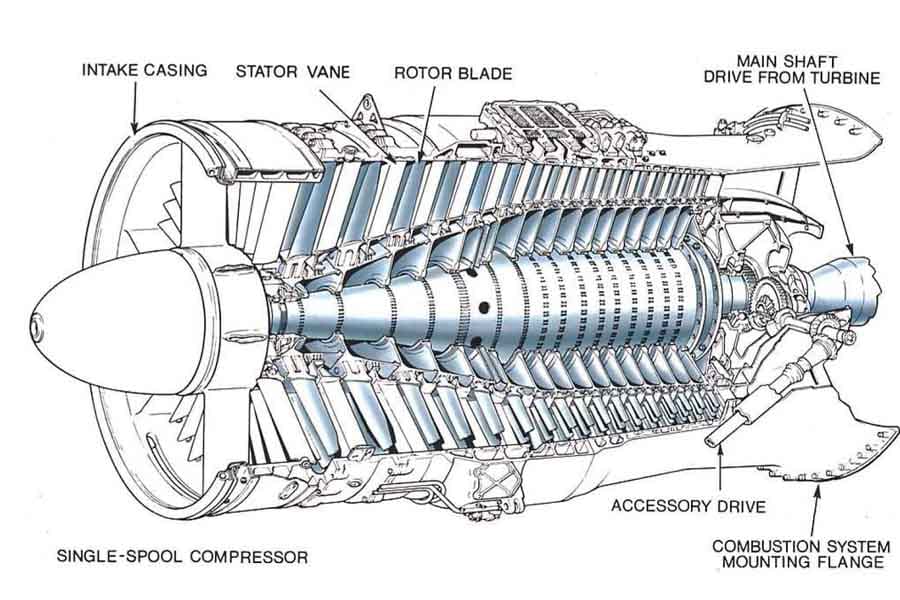

Axial Compressors: Revolutionizing Performance

One of the major advancements in compressor technology came with the introduction of axial compressors in 1872 by Dr. Franz Stoltz. These compressors offered superior performance and efficiency, paving the way for the high-performance compressors we rely on today.

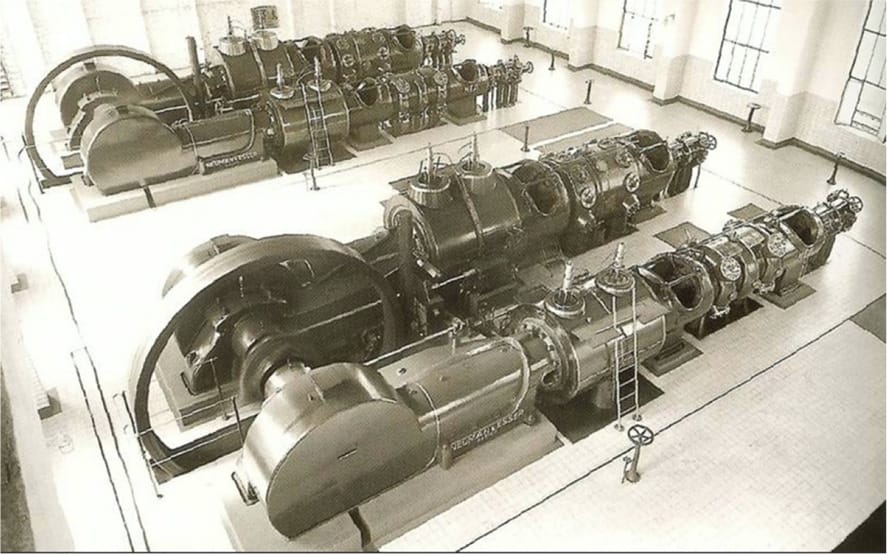

Modern Compressors: Cutting-Edge Technology for Enhanced Efficiency

Today, compressors are crucial in various industries, including air conditioning, energy production, and manufacturing. With the advancement of technology, modern compressors deliver superior efficiency, lower energy consumption, and greater durability. Axial and centrifugal compressors are some of the most advanced types used across diverse sectors, offering excellent performance and reliability.

Positive Displacement and Dynamic Compressors: Understanding the Difference

Modern compressors can be broadly classified into two categories: positive displacement and dynamic compressors. Positive displacement compressors work by moving a specific volume of gas with each pump cycle, ensuring consistent airflow. On the other hand, dynamic compressors function based on the speed of the gas flow, making them ideal for high-flow applications.

Conclusion: The Importance of Compressors in Modern Industry

The evolution of compressors showcases the remarkable journey from ancient tools to high-tech machines. Today’s compressors are essential in numerous industries, contributing to energy efficiency, reliability, and performance. Whether you require a compressor for manufacturing, energy production, or any industrial application, selecting the right one based on your needs is crucial for optimal performance and cost efficiency.

By leveraging cutting-edge technology, modern compressors not only help reduce energy consumption but also enhance productivity, making them indispensable in today’s industrial landscape. Ensure you choose the perfect compressor for your specific needs to improve operational efficiency and reduce energy costs.